|

|

(DPC)

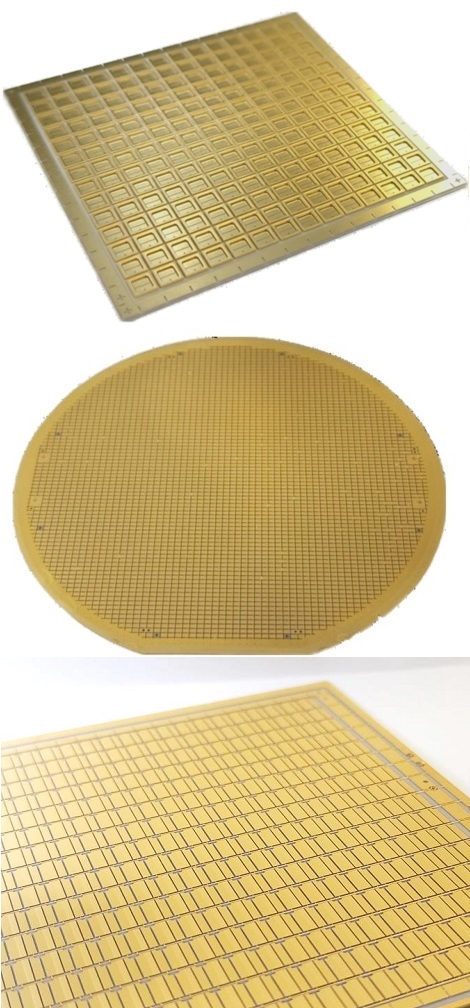

Advanced Heat Dissipation Ceramic Substrate

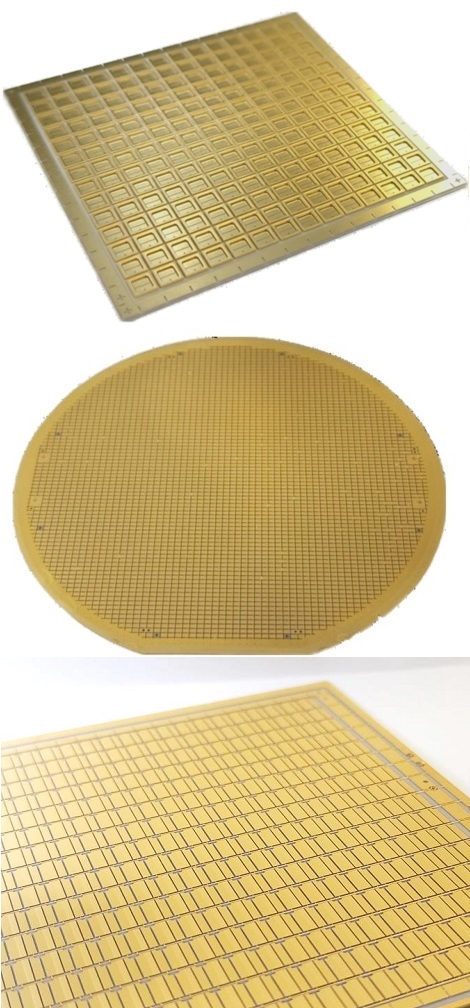

- Substrates for Laser Diodes

- Thin film metallization process technology, semiconductor lithography process, production of high-precision, high-reliability high-power heat-dissipating substrates suitable for various surface/vertical laser semiconductor packaging processes are all available.

- Application:

- TO-CAN laser packaged components

- VCSEL laser package components

- EEL laser module CoS package components

- Substrates for Power Components

- To meet the needs of electric vehicle applications that require high power and high frequency performance, offer thin film metallization process technology combined with the characteristics of ceramic materials to provide high thermal conductivity, high voltage resistance, good insulation, and other advantages.

- Application:

- Power components for IGBTs

- Power MOSFET components

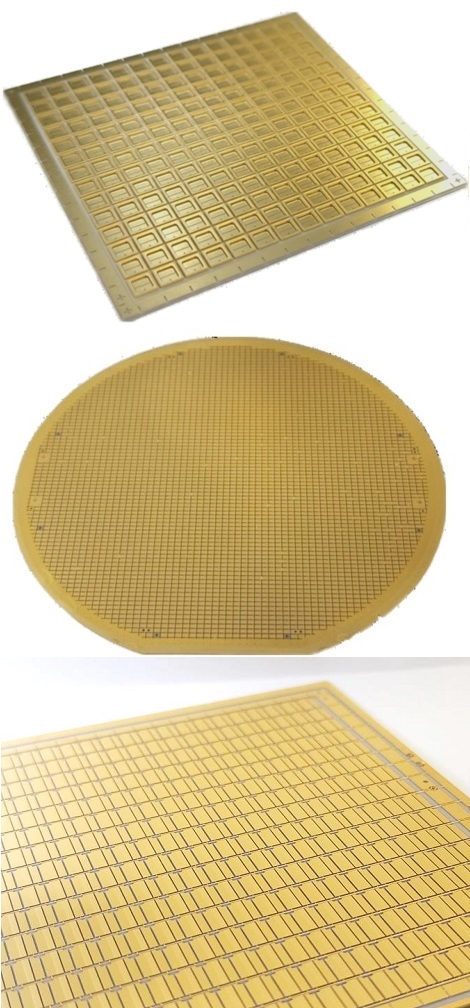

- Heat Dissipation Substrate for LED Package

- We provide highly customized graphics, circuits, and metal dam designs, as well as high reliability, high heat dissipation, and thin ceramic heat dissipation substrates, by combining the heat dissipation of ceramics with the conductor characteristics of metals. High-power lighting, stage lighting, packaging substrates for automotive lighting, infrared (IR), and ultraviolet germicidal lamps (UVA/UVC) are among the most common applications for the products.

- Application:

- High-powered lighting

- Lighting for automobile

- Infrared (IR)

- UV germicidal lamp

- Metallization Coating Foundry Service

- The products are primarily used in EMI/ESD, metal texture, reflectivity multiplication, and surface modification applications, and they offer a composite surface processing method for sputtering metal film processing.

- Application:

- Wafer metallization

- Decorative/functional coating

|

|

|

|